It is important that it be fully wound once a week or every day in the case of a 30 hour movement because of the timekeeping issues mentioned below.

Wind up wall clock stops running.

The easiest way to adjust this in the first instance is simply to tip the clock on the wall.

Some clocks will run faster if they are wound too tightly in the first 24 hours after you ve tightened the mainspring.

So simply wind it until you feel the spring come to a definite stop.

Wind it up until it stops.

So the first thing to check is that it is in beat.

This may not be physically level for the clock case.

If your timepiece has a tiny pendulum you may need to wind it more often.

If it s not doing this it will stop.

Open the clock face and inspect the clock hands.

If the clock won t run for its due period you re probably not winding it up fully.

Pendulum over swing if the bob on the pendulum hasn t first been immobilized or removed from the pendulum arm before the clock is moved the pendulum can over swing go past its normal arc and throw the clock out of beat then eventually the clock will stop.

Bend the hour or minute hand whichever is on top slightly toward you to create clearance.

Friendly advice and general diagnoses are always free and we love inspecting new clocks.

Feel free to give us a call or stop by.

Tock tick tock tick an adjustment must be made or the clock will stop.

Moving a mechanical mantel clock from one place to another is one of the most common reasons why it stops running and can result in one of the following.

Is your clock stuck or operating sporadically.

This can be done by either try leveling again from left to right by moving the clock very slightly from the bottom until you hear the most even tick tock.

If the beat is irregular like.

The pendulum should tick with an even beat like a metronome tick.

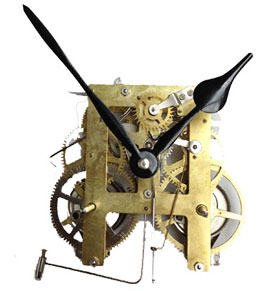

Dried oil and debris can clog and stop the clock mechanism.

If the simple act of lifting the lever is enough to stop the timetrain then you have a clue to work with.

Brushing the mechanical works with a soft brush such as a paint brush should dislodge any dust or dirt.

Even though it is impossible to over wind your clock it is also not necessary to wind it until the last possible click of the ratchet.

If dried oil is visible gently brush it away.

Another consideration is to find out if clock has lifted lever yet and gone into warning mode prior to striking.

Do not try to force it to wind any further.

To correct a spring driven clocks mantle or wall clock that is bonging the hour when the minute hand gets to 6 o clock instead of 12 o clock just count the bongs take off the minute hand and reinstall it on the clock pointing to 12 o clock then turn the hour hand to the hour you heard the clock bong and its done.

Turn the key slowly and just a half turn at a time.

You want to stop just short of the fullest wind possible.

The more you take the time to wind the more wear you are putting your clock through.

Push the hour hand back and forth gently to release it.